PLC designed specifically for industrial applications

PLC (Programmable Logic Controller) is a digital operational electronic system based on microprocessors, designed specifically for industrial applications. It combines computer technology, automatic control technology, and communication technology, using programmable memory to store operational instructions such as logical operations, sequential control, timing, counting, and arithmetic operations, and controls various types of machinery or production processes through digital or analog inputs and outputs. PLC is an important equipment in the field of industrial automation, characterized by reliable operation, programmability, easy operation, and simplicity.

The working principle of PLC

The working principle of PLC is based on the processing of input and output signals. It receives signals from external devices such as sensors through input modules, samples and filters them, and sends them to the central processing unit (CPU) for logical operations. The CPU makes logical judgments and calculations based on pre written programs, generates corresponding output signals, and converts them into control signals through output modules to achieve control of external devices.

Application scope of PLC

The application scope of PLC is wide, including but not limited to sequential control, motion control, process control, etc. Sequential control is the most widely used field of PLC, which is used to replace traditional relay sequential control and is suitable for scenarios such as single machine control, multi-level group control, and production automation line control. In terms of motion control, PLC provides single axis or multi axis position control modules for stepper motors or servo motors to achieve smooth motion control. In addition, PLC can also monitor a large number of physical parameters, such as temperature, pressure, flow rate, etc., to achieve closed-loop control.

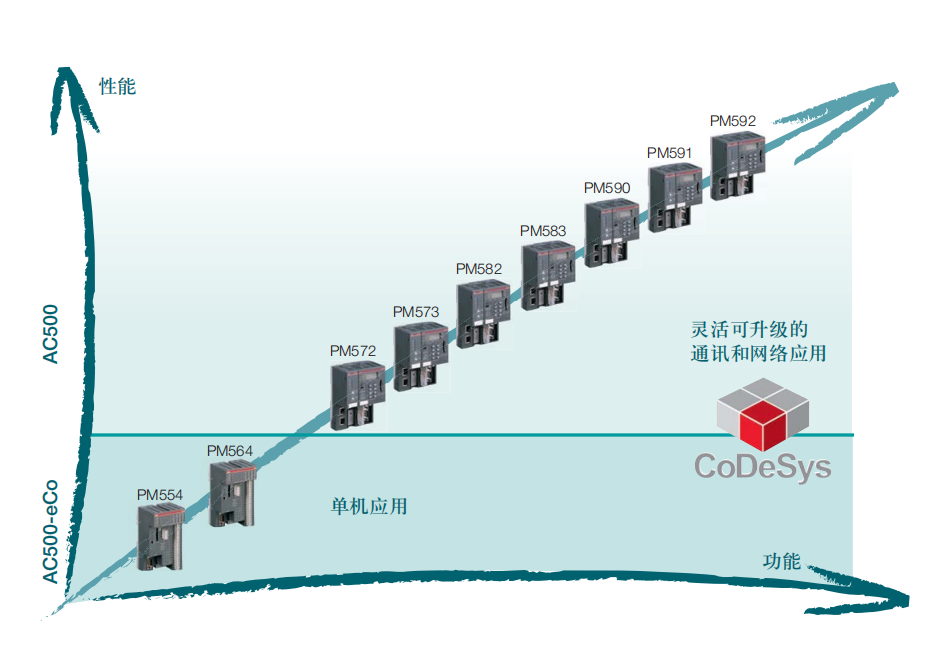

Classification of PLC

There are many types of PLC products, which can be divided into two categories based on their structural forms: integral and modular. The integrated PLC integrates power supply, CPU, I/O interface and other components into one chassis, suitable for small systems. Modular PLC divides each component into separate modules, such as CPU module, I/O module, power module, etc., suitable for large or flexible configuration systems. The characteristics of this modular PLC are flexible configuration, easy expansion and maintenance.

Bentley 3500 series module sup

Bentley 3500 series module sup

ABB module supplier Guizhou Yu

ABB module supplier Guizhou Yu

ABB supplier

ABB supplier

A6500-RC

A6500-RC