DCS stands for Distributed Control System

DCS stands for Distributed Control System. It refers to a technical solution in which multiple controllers work in coordination with each other to achieve system automation control. DCS is commonly used in industrial production, manufacturing, and processing industries, including chemical, pharmaceutical, food, pulp, and paper industries. They play an important role in monitoring and controlling the production process, optimizing processes, ensuring safety and reliability.

Distributed Control System (DCS), also known as Distributed Control System, originated in the mid-1970s and was initially developed by instrument manufacturers. At that time, it was mainly used in the chemical industry. It is developed on the basis of centralized control systems, integrating 4C technologies such as computer, communication, display, and control. It is a multi-level computer system composed of process control level and process monitoring level, linked by a communication network, with functions such as continuous control, batch control, logical sequence control, and data acquisition. DCS combines the advantages of decentralized instrument control and centralized computer control systems. Its architecture is a distributed, branching tree structure, which can be vertically divided into three levels: decentralized process control level, centralized operation monitoring level, and comprehensive information management level. Each level is independent and interconnected, and can be horizontally decomposed into different sub modules. For example, the decentralized process control level can be divided into on-site control stations, PLCs, intelligent regulators, and other measurement and control devices.

After years of development, although DCS has not undergone significant changes in its system architecture, its functionality and performance have been greatly improved through continuous development and improvement. Overall, DCS is developing towards greater openness, standardization, and productization.

DCS is a widely used technology in the field of industrial control, which effectively achieves monitoring and control of industrial processes by integrating and optimizing automation and control systems. DCS can be used to monitor and control different process parameters in factories, such as flow rate, pressure, temperature, liquid level, etc., thereby improving production, quality, and safety. In addition, DCS can adjust process parameters based on the real-time status of equipment and production requirements, and automatically control the required operations, including switches, valves, pumps, etc. This makes the production process more stable and reliable, enabling industrial enterprises to better control production costs, improve production efficiency, while reducing energy consumption and environmental pollution.

Bentley 3300XL vibration prepr

Bentley 3300XL vibration prepr

Bently3500 vibration monitorin

Bently3500 vibration monitorin

Bently Nevada 3500 Series onli

Bently Nevada 3500 Series onli

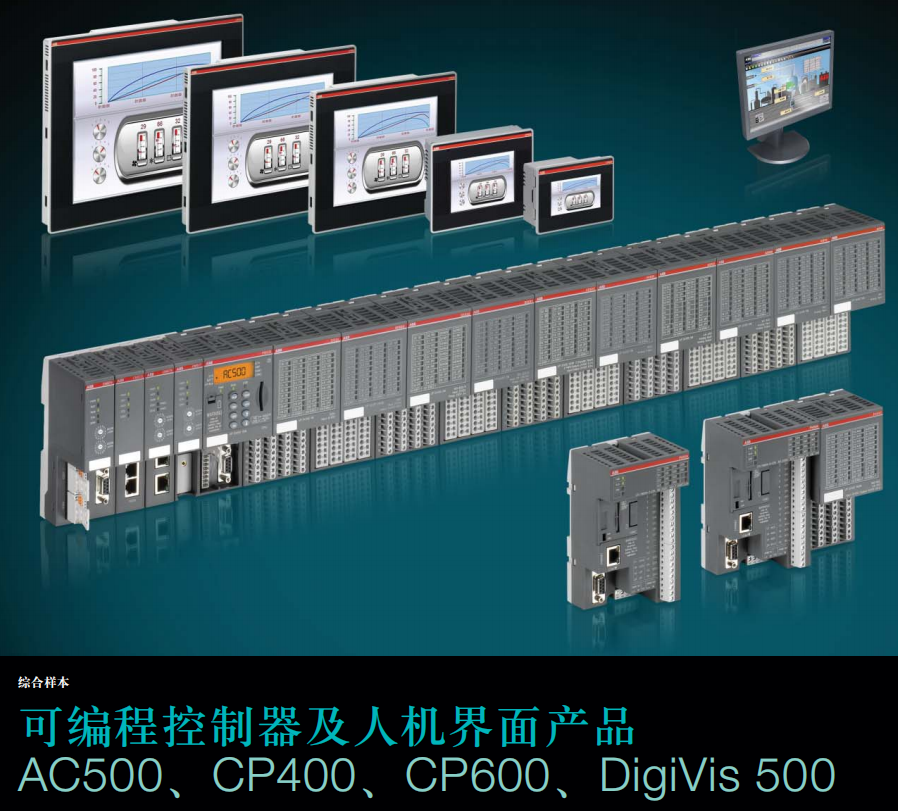

Advant Controller 31 series

Advant Controller 31 series