Bentley Nevada 990-10 Series Vibration Transmitter, High Precision for Industrial Control

Model:990-10-XX-01-05

Brand:Bently Nevada

Sensor Type:Vibration

Sensing Range:Not specified, typically covers a wide range

Sensitivity:Not specified, generally high

Output Type:Voltage

Installation Type:Non-contact

Operating Temperature:-40°C to +100°C

Package/Casing:Injection Molding

Characteristics:["High Temperature Resistance"]

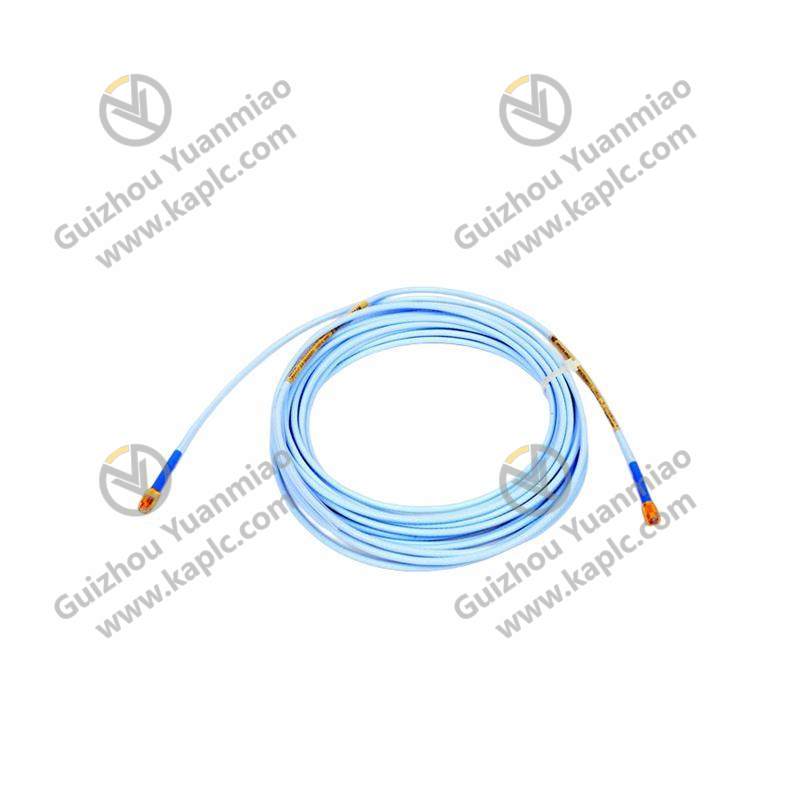

Termination Type:Gold Connector

Minimum Number of Packages:1

Application Areas:["Equipment"]

Item Number:004

Applicable Products:["Steam Turbine"]

The Bentley Nevada 990-10 Series Vibration Transmitter is meticulously designed to enhance operational efficiency by continuously monitoring and transmitting critical data on machine vibrations. This advanced technology ensures early detection of potential issues, allowing for proactive maintenance schedules and minimizing downtime.

Equipped with a robust sensing range and sensitivity, this transmitter accurately captures minute fluctuations in machine movements, providing precise readings that are essential for maintaining optimal performance. Its high-temperature resistance and non-contact installation make it suitable for demanding industrial environments where reliability is paramount.

The injection-molded casing offers a durable and protective enclosure that withstands harsh conditions without compromising signal integrity. Coupled with its gold connector terminal, the device ensures reliable electrical connections even under varying environmental conditions.

Integrating seamlessly into various equipment, the 990-10 Series is versatile enough to cater to a wide range of industrial applications, particularly in steam turbine operations where precision and reliability are critical for safety and efficiency. Its compliance with industry-standard certifications guarantees compatibility and peace of mind for users.

With its combination of advanced features and proven reliability, the Bentley Nevada 990-10 Series Vibration Transmitter is an indispensable tool for maintenance engineers and operations managers aiming to maximize the lifespan and productivity of their machinery.